SENQCIA’s R&D

SENQCIA's various distinctive products are developed based on a component design scale backed by high manufacturing technology and installation achievements.

These products contribute to reducing man-hours related to structural designing, construction efficiency, the comfort of living spaces, and achieving high economic efficiency.

These were born from the attitude of always facing the problems in the field and work style on the development of new technology with flexible ideas.

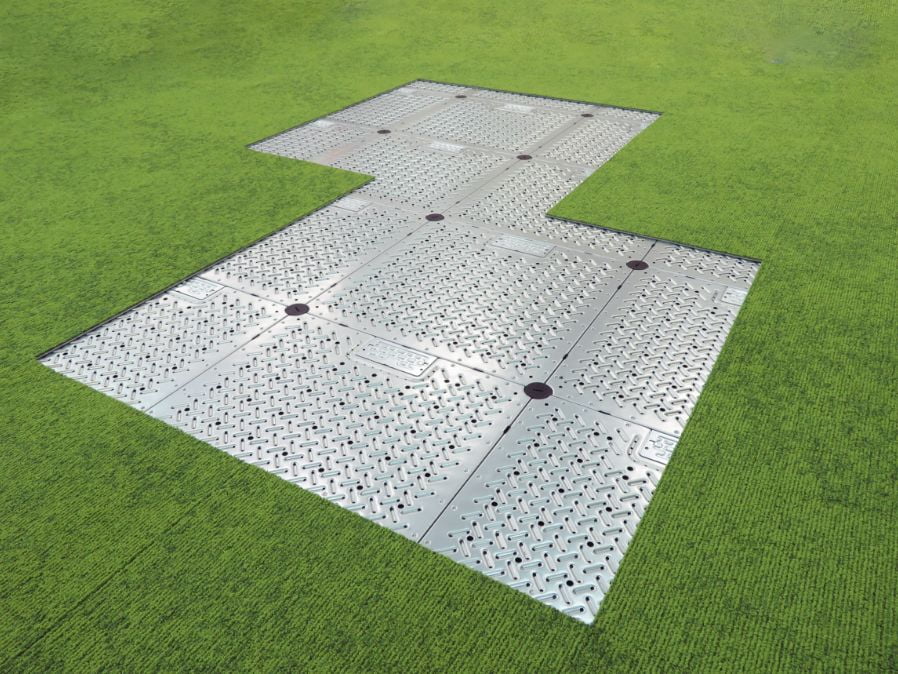

Leading the raised floor business with a wide range of technologies based on a long track record of sales

SENQCIA has been a leading company developing raised floor systems since the 1960s. Our Raised floor Systems are used not only in computer rooms, but also in general offices, clean rooms, and other facilities. The performance in each case has earned high praise from various customers. We consider a raised floor to be not simply a floor, but a functioning floor. For example, we have developed earthquake-resistant floors, seismic isolation floors, and full underfloor air-conditioning system that can create a comfortable office environment. We believe it is our mission to listen to these individual needs and keep searching for more advanced technology.

HIBASE System evolving with market needs

Since its launch in 1972, SENQCIA's HIBASE System has continued to evolve economic efficiency. Various improvements have been made to achieve miniaturizations and higher performances.

The biggest improvement in the HIBASE NEO System currently on the market is its newly developed base plate shape, which improves energy absorption by the column base. It has received a rating from the Building Center of Japan. It was an unprecedented construction system rating, with the Building Center of Japan’s extremely rigorous review. In response, it took more than three times as much as normal development projects to demonstrate the performance through experiments and FEM analysis, and then we were able to get the ratings and the accreditations.

Through-diaphragm system for column-to-beam connection squeezing column size - first standardized product in Japan

There is a strong need to reduce construction costs by making upper-floor column widths smaller than lower-floor ("column squeezing") at column-to-beam connections in steel-framed buildings, thereby increasing the effective building space and reducing the amount of steel. Column-to-beam connections were generally constructed using trapezoid steel welded box called taper tubes, but this was time-consuming in terms of machining and welding. We solved this problem with the development of the SMARTDIA System. By making it the first standardized product of its kind in Japan, we were able to reduce the total cost of column-to-beam connections to squeeze column.

HIRING System, the first standardized through-hole steel beam reinforcement in Japan

When making holes in steel beams to pass through pipes and cables, beams used to be conventionally reinforced by welding bracing plates or pipes around it to prevent a reduction in its strength. However, there was no standardized design ways nor fabrications which means time-consuming. We therefore developed our own ring-shaped reinforcing hardware and standardized system. This has dramatically simplified designing, fabrication, and construction process, significantly reduced the time and cost. Since its development, HIRING has undergone many improvements and remains which is popular with many customers.

Adoption of IMS; innovation management system

We define innovation as "providing new value" and distinguish it from technological innovation.

Today, we are in an era of saturation of products and services, and it is necessary for innovation to solve potential problems that customers are not aware of or have given up.

In this background, we adopted ISO56002: Innovation Management System (IMS) in April 2020. IMS is an international standard published in July 2019, is a guideline to encourage the realization of innovation by organizations.

All employees work together with diverse ways of thinking by IMS, we will keep a keen eye on changes in our customers and in society, and propose the value that our customers' needs.

In addition, we believe that IMS will function as a common language in the innovation co-creation process that accompanies collaboration between companies.

Flexible ideas created by engineers in various fields and with onsite perspectives

Our engineers have a variety of backgrounds. In addition, because of our installation services, we can become aware of issues and needs from an on-site perspective. Our strength is that we can combine such knowledge, know-how and technologies. We continue to develop innovative products under the themes of "products can be the great power with fewer materials" and "products can be installed at construction sites with less man-hours."

Evidence of trust. Numerous accreditations and ratings.

SENQCIA has actively obtained third-party accreditations, ratings, certifications, and assessments of the performance of our materials and construction systems, including certification from the Minister of Land, Infrastructure, Transport and Tourism and a rating from the Building Center of Japan. These accreditations make easier that customers adopt our construction systems and products with confidence. We never neglect efforts to build and enhance trusts with customers.

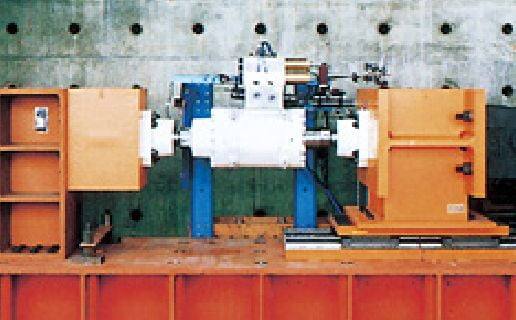

Substantial experimental facilities for various kinds of development

We have a variety of testing equipmentequipment for speedy in-house product development in a wide range of fields.

We also carry out R & D activities in cooperation with external institutions.

Samples of our test machines

- Dynamic testing machine: Shaking platform to check seismic performance.

- Static testing machine: Frames, hydraulic jacks, etc. that enable full-scale structural testing.

- Precision universal testing machine: A multipurpose testing machine that performs loading tests, etc., on floorboards.

- Rolling road tester: A testing machine in which wheels simulating a carrier truck are pressed against a floorboard and moved back and forth.

- Air conditioning test room: A test room used to check the performance of underfloor air conditioning.